slitting line

Coil machine cutting line is a lengthway cutting line for devide the metal coil into several strips.

First,slitting line will uncoil the coil with a decoiler, then cut the metal sheet longitudinal.Next, the tension stand can separating the steel coil to adapt the recoiler.That can make the steel coil has back pull power.In the end, the strips can be recoil into the recoiler system.

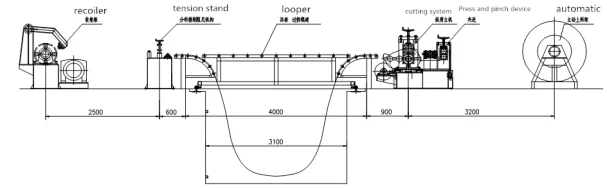

High accuracy metal sheet coil cutting machine slitting line work process

From right to left are:

Loading coil→Decoiler →Press and pinch device→Side guide device→Slitting system and scrap winder →Looper →Tension stand →Recoiler

Raw material:GI/ carbon steel

Material thickness: 0.25-2 mm(as your request)

Coil weight: ≤ 10 Tons

Coil width: 500-1500 mm

Usage: Support the coil and the hydrulic drives it expand and shrink.Loading the coil actively.

Work type: Hydrulic

Loading capapcity: 10 TonsComponent: Base, break system, main shaft, machine frame, diagonal bracing type expand and shrink system, hydrulic oil pump, motor, press coil system,etc.

Usage: Clamping the metal sheet and feeding to the slitting system.

Component: Base, casting vertical structure, sliding block, press shaft (2 pcs), cluth, cycloid gear reducer motor (3 KW),etc.

Usage: It equpment guiding device in each side and feeding wipe brush, to finished strips and prevent them from jumping and improve the slitting precision.

The slitting system has active shear and pull shear and can swich them meet all of precision requirement with different thickness.There is also have scrap winder device.

Cutter shaft diameter: Φ 150 mm

Cutter shaft material: 40 Cr with tempering treatment

Cutter material: 9CrSi

Slitting precision: ≤±0.05 mm

Usage: Because the slitting quantity is too many,there will happen strips don’t on a Level.The melt pit is necessary.

Usage: Separating the steel coil to adapt the recoiler.That can make the steel coil has back pull power.

Usage: It cooperates with the finished steel strips after first pre-dividing and second dividing to insure the even and tight quality of recoiler. Recoiling tension adjustable, recoiling speed adjustable.

Loading capacity: 10 Tons

Inner hole diameter: Φ508 mm

Component: Base,main shaft,machine frame, hydraulic diagonal bracing type expand and shrink system,adjustable-speed motor(45KW),reducer,screw rod, dividing shaft,etc.

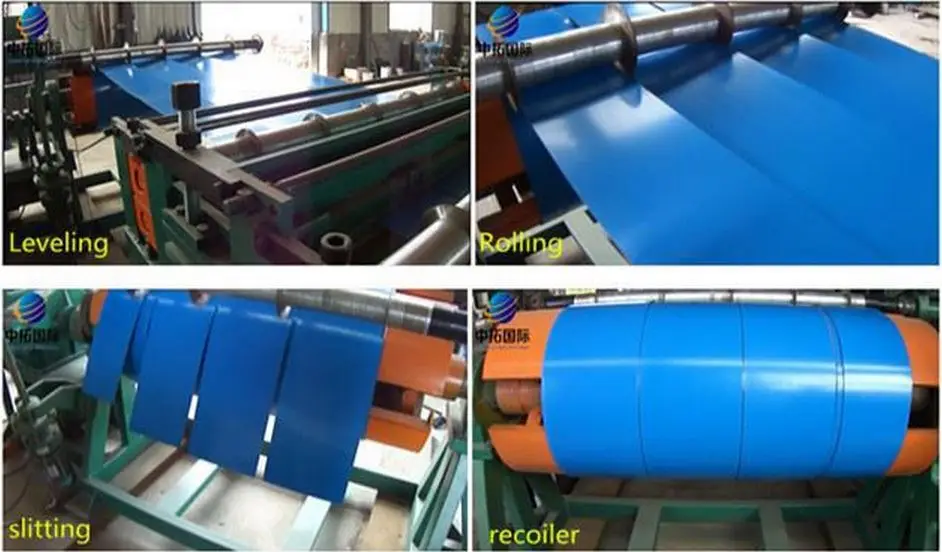

More photos about the slitting line:

FAQ:

1.Are you trading company or manufacturer ?

A:We are a 18 years of factory that specializing in roll forming machines, all machine is made by ourselves and we can provide customize service according to your requirement.

2.How can I ensure that I get high-quality machine?

A:As a manufacturer, we have a strict supervision and control of every step from raw materials purchasing, brands choosing to parts processing, assembling and testing.

3.How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and rich experience about machines and global market. We boast of professional engineer team and after-sale service team.

4.Which is your main market?

We supply machine to UK,USA, Austrila and South Korea. Besides, India is our main market, we have Indian sales manager and branch company in India.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations