stone coated production line

The stone coated roof tile making machine adopts the most advanced technology, basic of 0.4mm AL-zine coated steel,

surface covered with color vermiculite that experience high temperature sintering.

Stone coated production line maily part:

The all production line include two Manufacturing Process,the first one like roofing material making machine,

the second one is the most important. is the stone coated process.

What's the advantages of the stone coated roof sheet ?

The stone coated roof sheet is mainly used as roof panel or wall panel.

So the stone coated roof tile has many advantages as below:

Work flow of the stone coated roof tile production line

There are two options for you to choose according to your condition:

A1: Decoiler--roll forming machine --Auto bottom glue spraying section--Auto stone coated section--the fist time drying section--

Auto face glue spraying section--Auto face glue spraying section--the second time drying section.

B1:Decoiler--cutter machine--trimmer--stamping forming machine -- Auto bottom glue spraying section--Auto stone coated section--

the fist time drying section--Auto face glue spraying section--Auto face glue spraying section--the second time drying section.

Trimming machine

The trimming machine can trim the edge of metal sheet into the edge of stone coated.

Press machine

The press machine can press the metal sheet into stone coated shape.

Here are some technical parameter about the stone coated press machine

| Main motor power | 18KW |

| Number of pressing | 45-50 times/min |

| Motor of air pump | 5.5KW |

| Material of mold | Cr 12 |

| Weight of machine | 14 T |

Stone coated roof sheet glue spary section

This device can spary glue on the metal sheet surface automatically.

The glue color is same as the grit color.

Stone coated roof sheet spary grit device

After spary grit. the stone coated roof sheet need to be overturn manually on the shaft,

and then it will be send into the drying device.

These step need to be do secondary operation, then the stone coated roof sheet can be finished.

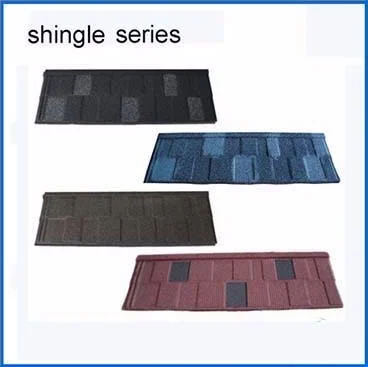

Some simples of the stone coated roof tile

Usually the stone coated roof tile have many model profile, different countries have different model.

We have many different profile for different market, if you are a new investment for this industry,

we can recommand you some popular model in your market for you to choose.

If your budget is not too high, we also can provide you the finished product----stone coated roof tile but not production line.

Try this roof tile in your market, if it can bring more business and profit for you, and then try to begin the production in your factory.

Contact me soon

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations