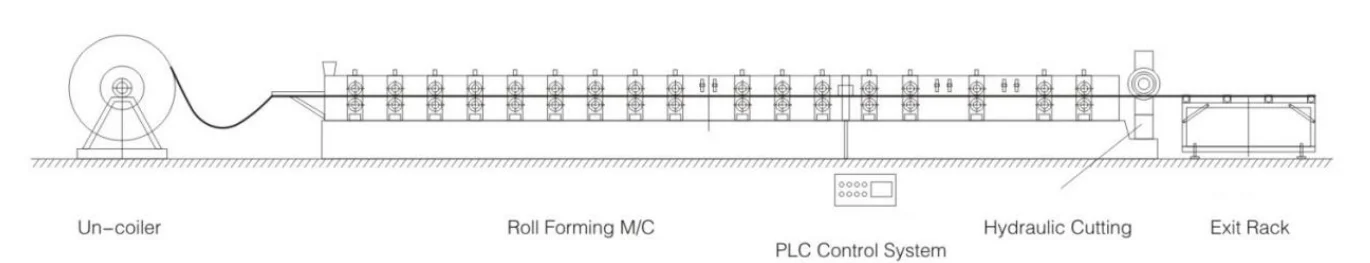

The cladding corrugated roof tile making machine work flow:

Uncoiling---Main roll former---Cutting device---Product collect table

What feature of our caldding corrugated roofing sheet making machine has?

1. The profile drawing is especially designed for India customer, so the profile is very popular in India market.

The machine can roll forming both 1220 and 1450 mm width, so you can get two kind of size to sell to your customer.

2. Feeding table or leveling beach:

3. Main roll former:

Meanwhile all the tilebox we will Boiled black and then it will never go rusting.

Technical parameter:

| Decoiler | Loading capacity | 5 Tons |

| Main roll former | Roller material | 45# steel with chromed treatment |

| Roller shafter material | 45# steel with quenched treatment | |

| Roller station | The roller will according to your profile drawing,diffierent dimension need diffierent stations to roll forming. | |

| Cutting device | Cutter material | Cr12 |

| Work speed | 0-15 m/ min | |

| PLC system | PLC brand | Delta |

| Frequency brand | Delta | |

| Counter | Omron | |

| Other electric part | Import brand |

Here I will show you some feature about our roof sheet roll forming machine

More details welcome contact me!

My whatsapp/ wechat: 008618733770188

1. How to visit your company?

-a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours), then we can pick up you.

2.How to get a quotation?

a.Give me the profile drawing and thickness,this is the important.

b.Other spicific requirements is welcome,such as the speed,power and voltage you want.

3.How about the machines for testing?

A:Warmly welcome to our factory supervise and inspect anytime;

B:We will arrange the machine test in our factory before the shipment.

C:If the customer can't come, we will provide the machine running video and photos to them.

4. How can I install my machine when it arrives?

A: We will send technician to install and train your people to use machines if required.If you need,our engineer will go to your factory for teaching.

5.What about your warranty?

A:Our warranty is 1 year, all machine part can be replaced for free within 1 year if broken(not including man made).And offer life time after sale service.

A.warranty:One year ,and we will provide the technical service for the whole life,Some spare parts are availale.

B.Training and service:the buyer charge of visa,round-trip ticket,food and accommodationoversea and USD 80 dollars per day for salary.

C.The advantage of my factory:we have a team of skilled engineers and one group for after-sale service.

D.We provide you the manual for installation,operation and maintenance English.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

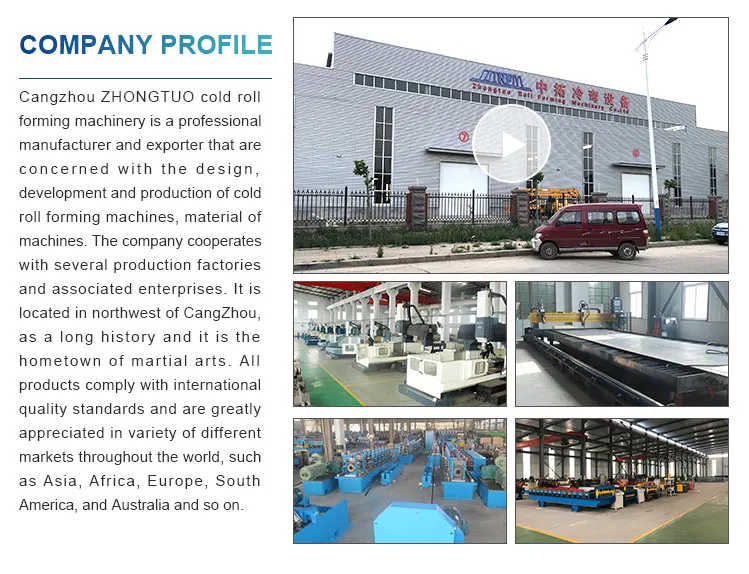

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations