cz purlin roll forming machine price

2) Loading width: max 300mm

3) Valid expanding range for coil inner diameter: 450-550mm

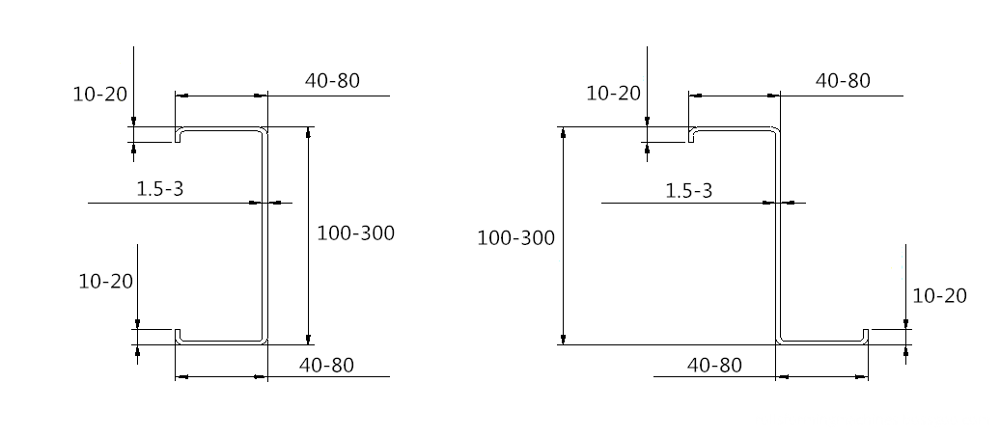

4) Valid width after formed: 100mm-300mm

5) Hydraulic pressure: 20Mpa

6) Hydraulic power:5.5KW

7) Feeding and leveling power: 4KW

8) Punching: Hydraulic pre-punching before forming,

9) Punching mould:Cr12mov

10) Cutting blade: Cr12mov

Advantages of cz purlin forming machine:

The interchangeable cz purlin roll forming machine can produce the c purlin and z purlin on one machine.

C and Z shape change on machine is the semi automatic type, it's much easier to make the adjustment.

There are two rotate handles on the forming system, need turn the rotate handle manually to change the shape from Z to C or C to Z.

The size of C shape and Z shape from 80mm to 300mm is adjustable automatically by PLC control.

PLC control program can support you do any size, just setup the order on the control panel and the machine will working automatically follow this order.

Due to the multi sizes for C purlin and Z purlin, we use the unlimited cutter on cutting system. The unlimited cutter is ajustable when form different sizes.

The cutter adjustment is manually but just take like one minute can be done. That means one set cutter can used for all the sizes as much as you want.

We adopt the vertical iron casting structure on the forming system, the iron casting struture are stronger enough to support the forming work.

Even the material thickness are thickness till 3mm and make the machine in a high stability.

Please see this picture, it's the transmission system. We adopt the gear box and cardon shaft driving on transmission system.

The gear box and cardon shaft is connected with the rolling shaft one by one, gear box material is iron casting, the gear material is 20CrMn Ti.

Gear box driving is much powerful compared with chains driving, and can improve the speed in a second.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations