steel pipe making machine

Zhongtuo high frequency steel pipe making machine adopts advanced welding technology and offers dual welding arcs, increased speed, higher deposition, superior mechanical properties and quality. It is widely applied for producing tubes for heat exchanger, refrigerator, frame of car, bicycle, fitness equipment, furniture, cooling machine, petrol transmission, construction industry, etc.

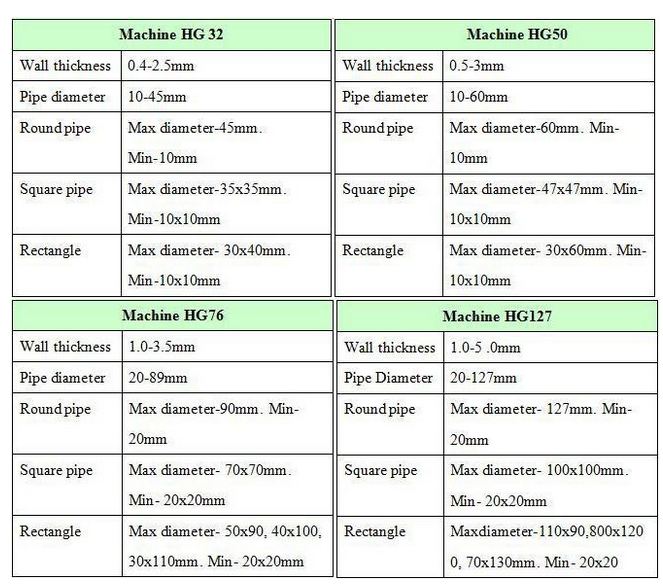

Now we have four types machines which are divided by wall thickness and diameter.

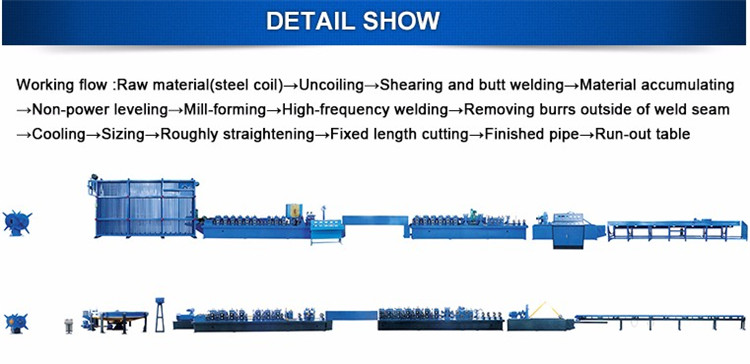

The high frequency steel pipe making machine is intended for manufacturing of round pipe from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.Finished product will be of round, square or rectangular pipe.

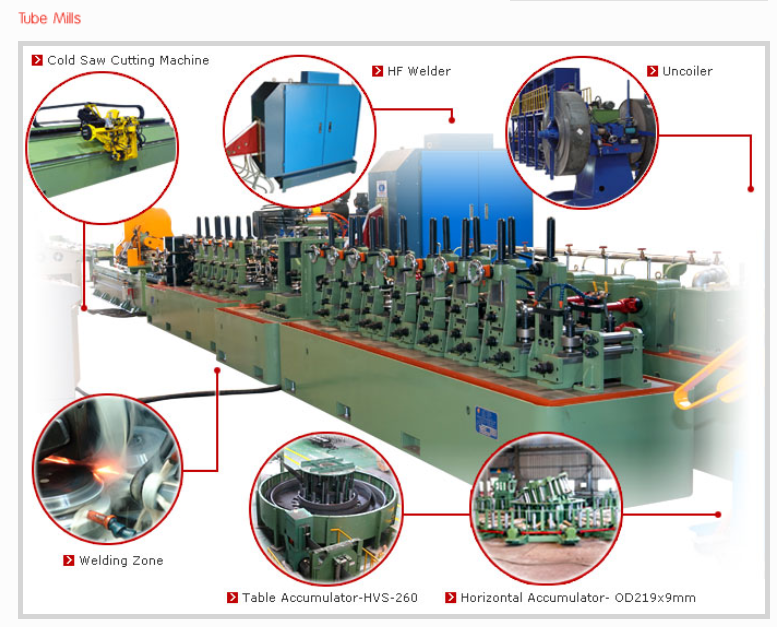

High frequency steel pipe making machine composes of a complete set of pipe forming machine, rotating capstan, decoiler, straightening machine, shearing,accumulator, tube mill section, flying saw and packaging device.

Features:

Through the use of PLC , system performance will be based upon the characteristics of the various sheet metals being used.

The material un-coiler uses an expand / shrink hydraulic cylinder that is mounted on an integrated steel frame. This allows for less malfunctions of the machine throughout its use.

The material un-coiler is equipped with a high-efficiency disc-type brake. Its tension is adjusted by an air pressure loop. Under these circumstances, the time for tension adjustments is reduced as well as the forcing of the monetary braking occurs thus freeing itself from the loosened coil.

The pre-loader is equipped with a DC various-speed motor drive, so that a synchronized speed that cooperates with the production line could be governed.

Slitting knives are mounted on an integrated frame with a separated transmission.

The datum plane and accuracy of the slitting knives axes are all to be fabricated within a measurement of 0.006mm. in tolerance, this makes allows for a higher duration of slitting knives as well as a much more accurate and larger number of outputs from the slitting line.

To make sure the stability of the slitting line is secure during operation, the tension controlled roll-up device with slip-differential structure has been designed for the waster.

The straight type tightener uses high elastics and resistive carpets as surface materials. This keeps the outputs of the line much smoother. In addition, it is also equipped with a pressure-balance device that keeps an even amount of pressure on both sides of the materials that are touching the tightener.

The Re-coiler is equipped with an improved high rigid holder that causes a reduction of lead-time. An air pressurized, adjustable back-pressure device is also equipped on the separator mechanism, this allows a constant hold-pressure to be reached for the recoil.

The enabling of self-tension design makes it able to retain a better tightness for recoil.

We can also provide you steel coil slitting line for this pipe line.

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations