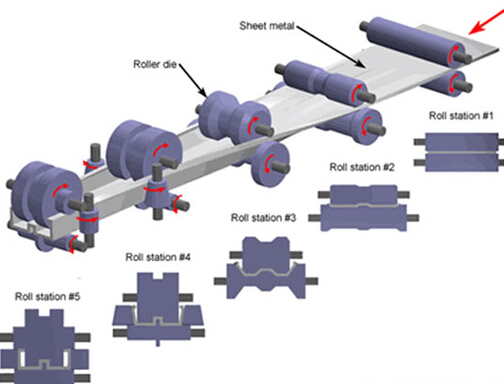

basic principles of roll forming machine design

The basic principles of determining the pressing path and the shape of rollers are as follows:

1, the shape of the rollers should make the strip have uniform and reasonable deformation with the least pressure type.

2, according to the selected top and bottom two rollers of the constant central axis, the roll of the shape of the structure, that is, longitudinal and transverse dimensions to determine and calculate. For a symmetrical shape, the axis is called an axis of symmetry.

3, the profile section of the roll is divided into several sections to calculate the length of each segment. At both ends of the selected centerline, the length of each section of the roll is constant in each passage.

4, the belt material passes each roller wheel, needs to consider the roller the smallest biting angle. One of the first several rollers to suppress the depth of a few, the back of a few rollers to suppress the depth slightly lighter. This mainly considers the strip through the first several rollers, metal materials will be hardened.