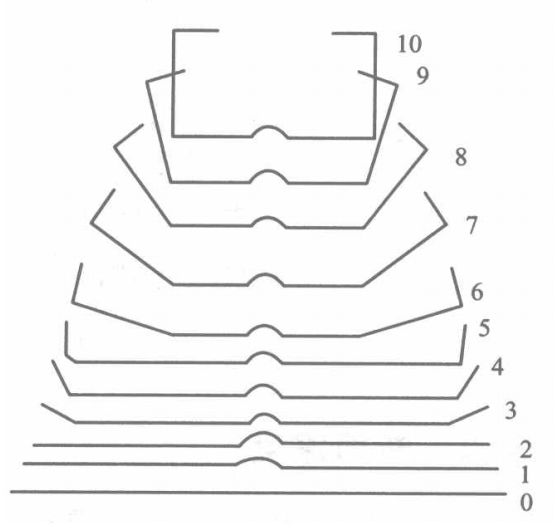

In the working process of the light keel making machine, the strip is gradually formed into the final shape. As the material passes through the mill, it is formed by rotating rollers.

The objectives of light keel making machine:

Form lighter products within given tolerances with a minimum of molding steps, is a minimum number of passes. If the number of molding passes is too fast, the product will suffer unacceptable stress and distortion. Too many passes will make the cost of tooling and processes too high.

After the molding criteria for the selected part, the designer has to determine the number of passes for each corner. Considering many factors, a short edge may require multiple passes. Rollers are expensive, and if the designer suggests using a lot of passes for molding, the equipment manufactured is not competitive. On the other hand, molding less than the ideal number of passes will result in expensive roll re-machining, adding roll sets, changing rolls, severe product scratches, prolonged installation or commissioning or being forced to scrap the entire roll. Since the 1980s and 1990s, some computer-aided design systems have been able to give the recommended number of times to calculate the forming stress. However, to date, whether the computer's calculation results are feasible still requires the roll designer to judge, or modify the calculation results to establish the correct number of passes. Once the number of molding passes and the order of molding are determined, and the amount of change is then determined, the designer will prepare a cross-sectional view of each molding pass. Computers are easy to create top, side, and three-dimensional views. If the designer is satisfied with the material flow, he can start the roll design.

The design of light light keel making machine rollers can vary from designer to designer, and there are many ways. This shows that there are no definite rules and formulae for the roll design. If the same cross section is given to different designers, different roll design drawings will be produced, among which there are high-quality design schemes and there are also poor ones.

A good set of easy-to-use light keel making machine roller designs may follow the following rules: Materials flow smoothly and in a desired manner. The number of molding passes is sufficient to avoid horizontal spacing and the introduction flange is too small, taking into account all requirements. No matter how good the design is, the roll must play a correct role. The following points must be fulfilled, such as accurate roll manufacturing, and the shaft of the light steel keel mill is not bent or loosened, and the shoulder positioning is accurate. In addition, the material must be matched with the molding process and the proper lubrication method should be used. The operator must be well trained to properly install, debug the roll and ensure the good operation of the production line. If these conditions are met, a good set of rolls will produce millions of feet of quality product.