Activity :transmission methods for roll forming machine

Mar 27, 2018

transmission methods for roll forming machine

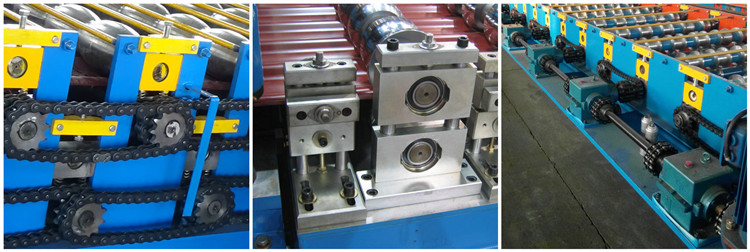

There are three main types mechanical transmission methods for roll forming machine.

1, chain transmission. The chain drive is a flexible drive. The basic parts consist of sprocket and chain. Movement and power are transmitted through the meshing of the teeth of the sprocket with the chain.2, gear transmission. The chain transmission has no elastic sliding and overall slip phenomenon, and thus can maintain an accurate average transmission ratio, and the transmission efficiency is high, generally about 95%. And the chain oil does not have to be as tight as the band, and the radial pressure acting on the shaft is very small. Compared with gears, the chain drive has lower manufacturing and installation accuracy requirements and lower costs. At the same time, in the long-distance transmission, the chain drive is much easier in structure than the gear.

3,chain and gearbox. A gearbox is a mechanical method of transferring energy from one device to another and is used to increase torque while reducing speed. Torque is the power generated through the bending or twisting of a solid material.

In a situation where multiple speeds are needed, a transmission with multiple gears can be used to increase torque while slowing down the output speed. The same principle can be used to create an overdrive gear that increases output speed while decreasing torque.