trapezoid roof sheet roll forming ma

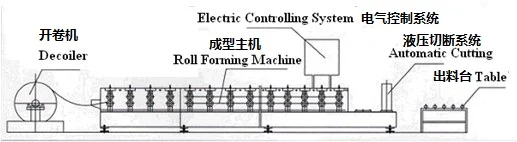

Uncoiling---feeding material---main roll former---cutting length---running out table

Raw material:

Material: PPGI/ GI

Thickness: 0.4-0.8 mm

Effective width:750 mm

Feeding width:914 mm

Decoiler:

As your requirement, we perpared several kinds of decoiler for your choose.They are with different configuration and parameters.

This is a 5 Tons manual decoiler (10 Tons can be done).

It's a economical choice.

You need put on the coil manualy and the material will be drive by the main roll former.

This is a hydraulic decoiler with a loading car.

The load car can be controlled to loading coil and align to the roller by go up and down.

This is high effective, the cost in higher than manual decoiler.

Main roll former

Main motor power:3 KW

Work speed:8-12 m/min

Roller material:45# steel with chromed treatment.

Roller shaft material:45# steel with queached treatment.

Roller shaft diameter: Φ 70 mm

Transmission: By chains drive

Roller station: 14 stations

Stracturer: Middle plant welded stacturer.

Frame thickness: 20 mm

Machine frame: 350 H steel with diagonal bracing inside.

Cutting system:

cutter material: GB-Cr12, give one free as spare part

work type:hydraulic

drive method:by pillar type cylinder

hydraulic motor power:3 KW

PLC control system:

We choose the high quality PLC system box. The cost of box is higher than other manufacturers in a same price level (The PLC part brand can be customized).

PLC brand: DELTA brand

Frequency brand: DELTA

Screen type:Touch screen and have buttons on it.

You can set up cutting length, and quantity on the screen.

Running out table:

Normal confirguration

Length:3 m

Width:0.5 m(adjustable)

Material:square pipe welded

Contact person:

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations