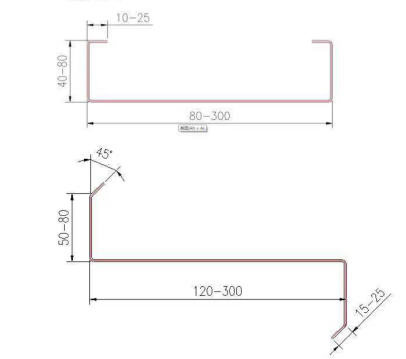

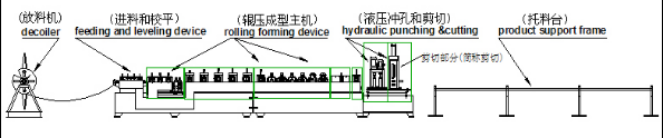

C/Z purlin interchangeable roll form

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations