channel roll forming machine

Features:

This c channel steel roll forming machine is the most popular one among the customers in the metal industry construction for metal or steel section materials.Industrial building and construction projects rely on drywall steel stud systems. The quick installation and light weight characteristics of steel framing makes this an ideal product. These tools are engineered to match standard stud sizes used in commercial building.

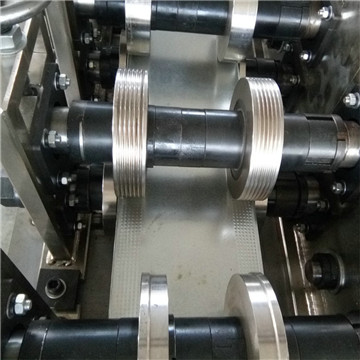

The rollers are make up with Cr12Mov material, which is more wear-resistant. This c channel roll forming machine adopts non-stop cutting method, with a speed of 25m/min.If you are not satisfied with this seed, we have another option. With the help of servo tracking cutting system, the speed can up to 50m/min.

Technical Parameters:

Raw material: Galvanized steel coil or Cold rolled steel

Yield strength of raw materials: 235MPA-345MPA

Material thickness: 0.3-0.8mm

Roll forming speed: 20-25m/min

Material of Roller: Cr12Mov

Shaft Material: High grade 45# steel with tempering

Drive type: gear

Motor Power: 3 KW

Material of punching dies: Gcr12 quenched

Material of cutting dies: Gcr12Mov quenching treatment 58-60°

Hydraulic power for cutting: 3KW

Control system: Delta PLC, Inverter and Omron encoder

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations