Stud and Track Roll Forming Machine

stud track roll forming machine is a kind of machines that can forming the steel plate to the required profiles. Normally this kind of steel keel roll forming machines use the galvanized steel plate as the raw material, and this material are coils type, this will let the machine produce continuously, so it will increase the efficiency of the production.

Our stud track roll forming machine adopt the middle plate welded structure, this will let our machine stable and strong. The middle plate welded structure is more strong than the square pipe welded structure. And for the roller fixer, our machine adopt the memorial arch type. This kind of memorial arch roller fixer is much more precision than the middle plate welded roller fixer. Our machine roller adopt the Gcr12 material, this material is the best material for the forming rollers, we gurantee the rollers no damage within five years, if have damage within five years and then we change new rollers for you in free.

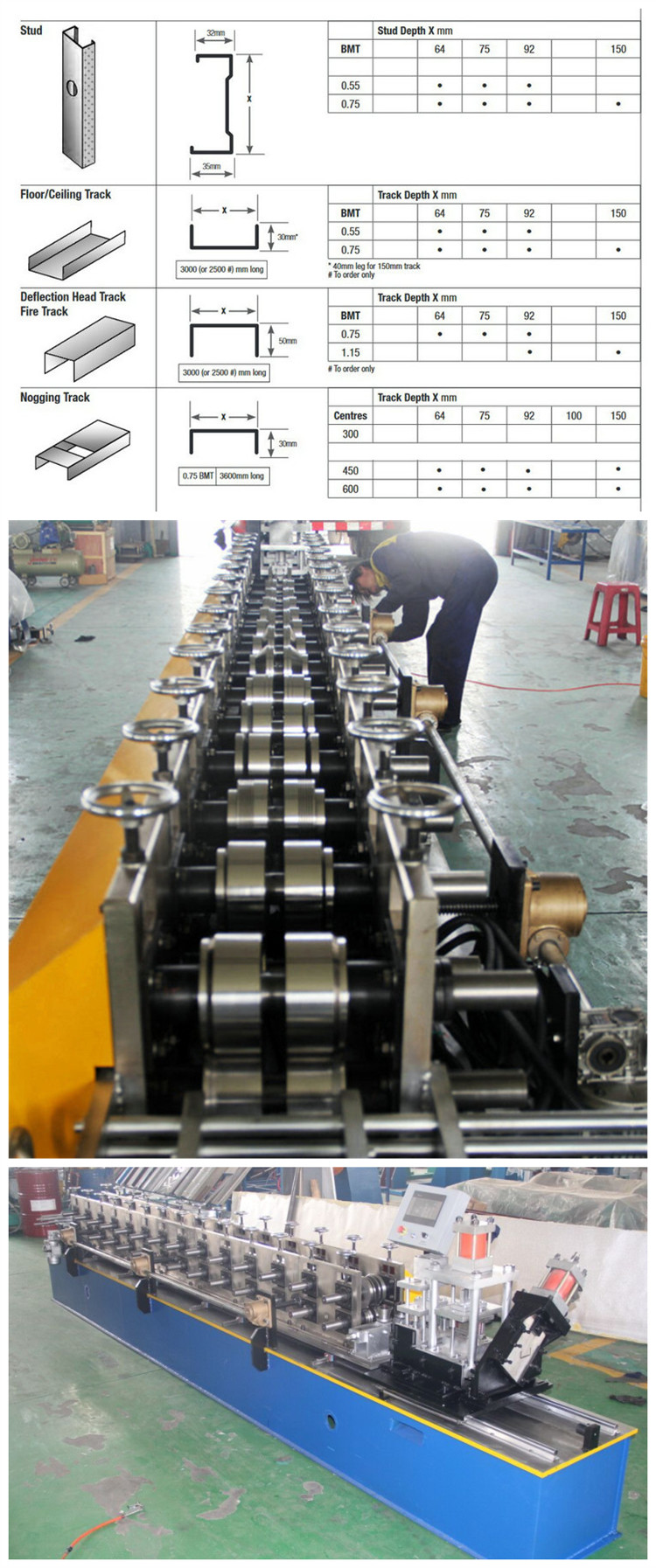

This stud track roll forming machine can produce tracks with different width. As you can see from the photo. There are linears on one side of the machine. When you need other sizes, only need to remove along the linears and change the cutting mould. Then you can get precious tracks.It is more easier and quick than the machine with changing spacers for different sizes.

1.The machine is stable,no noise,no shake.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable.

3.cutting machine is characterized by stable driving, easy operation.

4.hydraulic system use the hydraulic pump, long operating life,no noise.

1.Take continuous production,there is no need to change the rollers in rough-forming section.

2. rollforming machinery co,ltd finished with good flatness bending pressure performance is good, automatic fixed-length cutting, automatic punching, high degree of automation, quick and easy installation,

3.the product can be used as medium-sized industrial and civil buildings the main force structure ,such as factories, warehouses, machine garages, hangars, exhibition halls, theaters, stadiums, fairs Shed roof and wall flat load bearing support.

Raw material: Galvanized steel coil or Cold rolled steel

Yield strength of raw materials: 235MPA-345MPA

Material thickness: 0.3-0.8mm

Roll forming speed: 15-20m/min

Material of Roller: Cr12Mov

Shaft Material: High grade 45# steel with tempering

Drive type: gear

Motor Power: 4 KW

Material of punching dies: Gcr12 quenched

Material of cutting dies: Gcr12Mov quenching treatment 58-60°

Hydraulic power for cutting: 3KW

Control system: Delta PLC, Inverter and Omron encoder

steel rolling machines_industrial steel rolling machines_steel plate rolling machines_steel re rolling machine_roll forming machine - ZhongTuoCN SteelRollingMachines

Add:Silver Spring, plot no G-6, A-wing, Shop no 20/21,opp. Dena Bank, Taloja Midc, Raigad, Maharashtra, India- 410208 Factory: Botou city, Hebei Province, China

whatsApp/Wechat:+86-18733770188

·Your personal informations